System Audits

Is Your compressed Air System Efficient?

Is your compressed air system running efficiently?

Do you know how much it costs to run your compressed air system? In most case compressed air owners and operators have no answer to these questions. A quick trip to the compressor room reveals the reason why; there are no instruments installed to measure consumption related parameters.

If you are not measuring these key performance indicators chances are that your system is consuming excess power leading to higher operating costs. Properly outfitting your system with these monitors can go a long way in determining problems, revealing waste, and pointing the way to solutions.

It is time you to started keeping an eye on your compressed air efficiency and costs to improve your profitability. You can’t afford to wait.

Our compressed air system audits review and diagnose your compressed air systems.

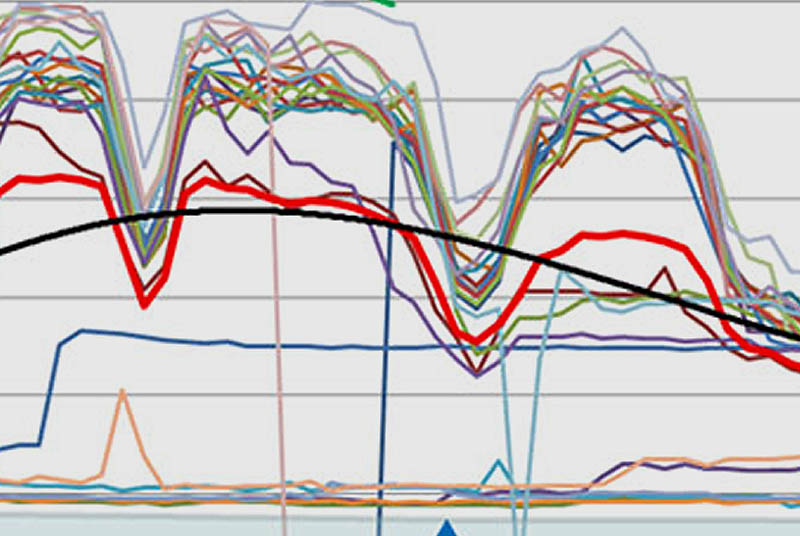

They are performed by DOE Qualified AirMaster+ Specialist and include a minimum of 7 days of data logging of system-wide parameters with the objective of developing proper alignment of supply and demand sides for optimum efficiency, energy savings, and reliability. Each audit is custom-tailored to fit the client’s needs; however, the following aspects are included:

- An overview at a cost per cubic feet or m3 of compressed air.

- The requirement of the plant for compressed air? Leak level.

- Compressed air requirement variation along the day/week?

- Short and long term plans to establish basic control and management of the air system

- A general guide the user can follow to continue increasing system efficiency

Probably your company is looking for different ways to save money to increase earnings or making new investments. There is a hidden solution in your compressed air system waiting for you.

We are here to help you improve your energy efficiency by reducing electric consumption and saving money with the added value of reducing upstream greenhouse gas emissions.

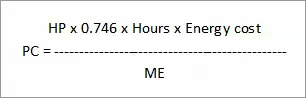

To establish your estimated annual electrical bill to produce compressed air in your company, you can use the following formula:

Where:

- PC is the Power Cost (annual)

- HP is the total horsepower in air compressors running over a determined time

- 0.746 is the conversion factor from HP to kW

- Hours is the hour per year your system is running

- Energy cost is the cost the company pays per kWh (add last 12 electric bills and divide by 12)

- ME is the motor efficiency. Use .9 if you do not know it.

- For example, a company that pays 0.06 $/kWh has 400HP running along 4,160 hours a year (16 hours a day from Monday to Friday). The estimated company cost to run the compressed air system is $ 82,756 per year.

- Considering that you can have energy consumption reductions of 20 to 30% your savings will be $16,500 to 24,800.

Please contact us to request a quotation for your system audit.